文章探讨了信息技术(IT)与运营技术(OT)的区别及其对工业安全的影响。IT侧重于信息管理和业务自动化,而OT专注于控制物理过程和管理工业资产。两者在架构、接口、安全性和支持技术的生命周期上存在显著差异。实际案例显示,在OT环境中错误应用IT方法可能导致生产中断或威胁人身安全。文章强调了理解这些差异的重要性,并建议在设计安全措施时需特别考虑OT系统的独特需求。 2025-7-30 10:17:33 Author: payatu.com(查看原文) 阅读量:19 收藏

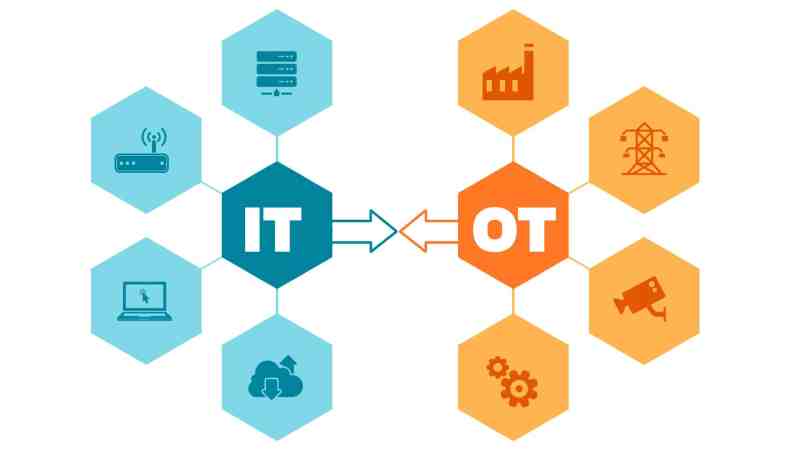

IT vs OT

Ever heard someone casually say, “OT is just IT with industrial devices”? I get the temptation—but it’s way off the mark. Moral of the story: OT isn’t your average office network—it’s mission-critical, physical, and way less forgiving. This kind of thinking can get systems broken, processes halted, or worse—someone hurt.

In the first blog, we learnt the foundations of Industrial, ICS, and Cyber-Physical Security.

This second blog in our OT Masterclass series is here to help you clearly see what makes OT different. If you’re a student, early-career engineer, or just someone curious about how factories stay secure, this one’s for you.

Goal for This Blog

By the end of this blog, you’ll understand how Information Technology (IT) and Operational Technology (OT) differ—not just in tools, but in philosophy. We’ll talk priorities, practices, risks, and real examples. You’ll also learn what happens when someone applies IT instincts to an OT system without considering how differently it behaves.

“IT and OT: Think of Them Like Cousins, Not Twins “

Let’s Paint a Picture

Imagine this: In an office, a new update rolls out for everyone’s email system. It’s tested, pushed at midnight, and everything’s back to normal by morning. Now, picture a bottling plant.

The touchscreen interface (called an HMI) that controls the conveyor line runs on a really old version of Windows. You want to update it? The vendor says the update might crash the software. There’s no backup. And that conveyor? It fills ₹40 lakh worth of product per day.

Would you still install that patch? That’s the difference.

How IT and OT Think Differently

This part is important. An IT security analyst might think in terms of logs, firewalls, or phishing attempts. An OT engineer thinks in cycles, sensors, control logic, and cause-effect chains.

Neither is it wrong. They’re just solving different problems with different tools.

⚠️ Same Threats, Different Consequences

The impact of cyber threats in IT vs OT environments isn’t just digital — it’s physical.

Threat Category

Viruses & Malware |

Ransomware Attacks |

Targeted Malware |

Denial of Service |

Code Injection/Fuzzing |

IT/Commercial Systems

| • Data Loss • Financial Impact • Reputational Setback |

| • Productivity Loss • System Downtime • Operational Disruption |

| • Unauthorized Access • Privacy Breach |

| • Temporary Downtime • Reduced Availability |

| • Application Errors • Security Integrity Compromise |

OT/Industrial Systems

| • Data Loss • Financial Impact • Reputation Damage 🔴 Risk to Human Life |

| • Production Halt • Operational Paralysis 🔴 Potential Safety Threats |

| • Loss of System Visibility 🔴 Loss of Equipment Control |

| • Critical Service Disruption 🔴 Process Instability or Blind Spots |

| • Equipment Behavior Anomalies 🔴 Potential for Physical Damage or Unsafe State |

🔴 Note: In OT environments, cyber incidents can affect human safety, production continuity, and compliance obligations—far beyond data loss.

The Protocol Conversation

In IT, we use HTTPS, SSH, SMB—most with encryption and strong user controls. In OT, you’ll hear about Modbus, DNP3, PROFINET, and others. Many of these were invented before cybersecurity was even a concern. They often send data in plain text. Some don’t even support passwords.

That doesn’t mean OT ignores security—it means you need to design protection around legacy systems, not inside them

Key Differences That Actually Matter

| Technology Areas | Information Technology | Operational Technology | |

| Purpose | Managing Information, Automate Business Processes | Managing Assets, Controlling Technology Processes | |

| Architecture | Transactional or Batch, RDBMS or Text | Event-Driven, Real-Time, Embedded Software, Rule Engines | |

| Interfaces | Web Browser, Terminal and Keyboard | Sensors, Coded Displays | |

| Ownership | CIO and Computer Grads, Finance, Procurement | Engineers, Technicians and Line Managers | |

| Connectivity | Corporate Network, IP-Based | Control Networks (Increasingly IP-Based and Wireless) | |

| Security | Availability | Delays, generally accepted | 24 x 7 x 365 |

| Security Awareness | Good in both private & public sectors | Very poor, except for physical security | |

| Security testing/Audit/Assessment | Scheduled & mandated | Occasional testing (for or after outage/incident) | |

| Physical Security | Secure | Remote & unmanned | |

| Application of Patches | Regular/scheduled | Slow (vendor-specific) | |

| Support Technology Lifetime | 3 to 5 years | Up to 20+ years | |

| Change Management | Regular/scheduled | Rare | |

| Time Critical Content | Delays, generally accepted | Critical due to safety & ongoing production | |

| Outsourcing | Common/widely used | Rarely used | |

| Examples | ERP, SCM, CRM E-mail, EAM, Billing | SCADA, DCS, PLCs, Modeling, Control Systems | |

🧯 When IT Breaks OT: Real Incidents

💥 You just saw the theoretical differences? Cool. Now let me show you what happens when someone forgets them.

- Schneider Electric Patch Disruption (2017): A Windows 10 update broke the engineering software used to configure PLCs (EcoStruxure Control Expert). Engineers couldn’t download programs or monitor logic. Production in several plants slowed or stopped.

➡️ Lesson: Even standard patches can disable the lifeline of OT [1].

- AV Update Crashes SCADA HMIs (Reported Case): An antivirus update deployed overnight at an automotive plant flagged and quarantined DLLs critical to SCADA interfaces. By morning, the engineering team couldn’t connect to HMIs. Production was halted for hours.

➡️ Lesson: What looks like threat prevention in IT can break trusted binaries in OT environments [1].

- Robot Moved by Ping Sweep (NIST SP 800-82 R3 Case): A routine IT network scan (ping sweep) caused a robot to move unexpectedly. It happened because the scan hit a controller with improperly handled packets.

➡️ Lesson: OT devices don’t expect random traffic. Even a basic ping sweep can have kinetic consequences [1].

- Printer Discovery Tool Crashes HMI (NIST SP 800-82 R3 Case): An IT department’s printer discovery tool flooded the OT subnet with broadcast traffic. HMIs overloaded and crashed due to buffer exhaustion.

➡️ Lesson: Even benign discovery protocols can overwhelm fragile OT systems not designed for IT-style traffic [1].

- Active Directory Policy Lockouts (NIST SP 800-82 R3 Case): An IT-administered password policy rollout caused engineering workstations to lock out due to failed service account logins. Engineers lost access during scheduled maintenance.

➡️ Lesson: Domain-level security rules applied without OT coordination can lock out operational teams at critical moments [1].

⚠️ Thought Experiment: In June 2025, a faulty CrowdStrike update led to global outages of Windows systems. While no direct OT disruptions have been confirmed yet, imagine if an HMI, historian server, or engineering laptop used in an OT environment had the Falcon sensor installed and auto-rebooted. The loss of control, visibility, or programming access during a critical process could have had cascading physical effects. This event is a modern reminder of why IT-grade updates must be OT-tested. (Reference: CrowdStrike Falcon Sensor global incident, July 2024)

⚙️ Smart Tech in Industry: What Changes?

These days, OT systems aren’t staying isolated. Thanks to Industry 4.0 and IIoT, factories and plants are adding “smart” devices everywhere.

- Sensors now report to cloud dashboards.

- Valves are adjusted via mobile apps.

- Maintenance alerts come from AI/ML models.

That sounds awesome—but it comes with new cybersecurity challenges:

- Remote access to engineering tools without proper controls.

- USBs used in field laptops that aren’t scanned.

- Network switches carrying both office and machine traffic.

Every new connection is a potential entry point. Especially when the tools weren’t designed for exposure [3][6].

Try This: Spot IT Thinking in OT Systems

Let’s do a quick reflective check. Imagine you manage a factory’s control room. Here are 3 real-life scenarios. For each one, decide:

- What could go wrong in an OT setting?

- Write your thoughts in a notebook

- Is this an IT practice that could cause OT issues? Yes/No

- Scenario 1:An automatic antivirus update is rolled out overnight on operator workstations running critical HMIs.

- Scenario 2:Network admins schedule a company-wide Windows update for all connected devices, including control room servers.

- Scenario 3:A new, strict password policy is pushed out, locking user accounts after 3 failed login attempts, even on engineering laptops used to maintain PLCs.

Scenario 1:

Yes, this is IT thinking. Automatic updates may disrupt OT operations if critical files are quarantined or deleted, causing production halts and loss of visibility.

Scenario 2:

Yes. Unscheduled OS updates could reboot essential machines, risking downtime, lost production, or unsafe process states.

Scenario 3:

Yes. Strict policies designed for IT can lock out necessary maintenance tools in the middle of an operation, causing delays or blocked recovery in an emergency.

Now write one more scenario that you can imagine. Now ask: What could go wrong if this happened during production?

Wrapping Up

IT and OT serve different masters. IT protects data. OT protects operations.

You don’t need to choose a side—but you do need to understand what matters to each. That’s the only way to build systems that are both functional and secure [1][2].

References

[2] International Society of Automation (ISA), “ISA/IEC 62443 Series of Standards”

[4] Dragos, “TRISIS Malware: Targeting Safety Systems in Critical Infrastructure,” Dec. 2017

[5] ESET, “Industroyer: Biggest Threat to ICS Since Stuxnet,” Jun. 2017

[6] NIST, “Cyber-Physical Systems (CPS),” CPS Public Working Group

[7] Wikipedia, “2024 CrowdStrike-related IT outages.”

Coming Up Next: Industrial Control System Components

Next time, we’ll break down the major building blocks of OT systems—PLCs, HMIs, RTUs, SCADA, and DCS. You’ll learn what they do, how they’re attacked, and what it means for your future in OT security.

Catch you in Blog 3!

如有侵权请联系:admin#unsafe.sh